Provisions for adequate combustion. Normally CS plates 6mm thick are used as casing material.

Thermal design of the heater.

. 250 Design Inlet pressure 107 bar Normal 117 bar Design Operation pressure 85 bar Total duty heater absorber 70 10 6 kcalh Normal. It uses air oxygen from the room in which it is installed. The metal plate is used to enclose the fired heater.

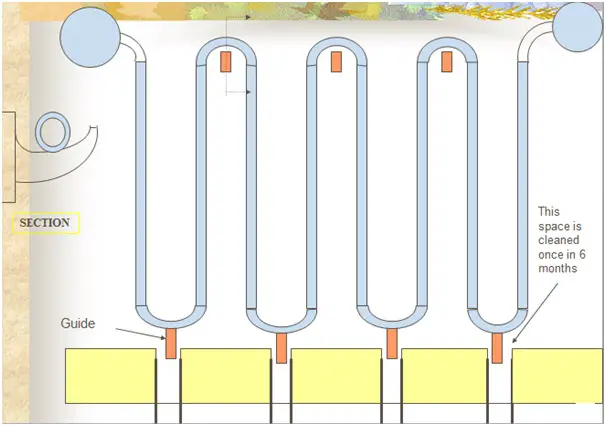

It may be as simple as a written procedure for manual intervention or it may be a fully automated emergency shutdown system. D tube TubeSpace2Sin piNoTubes212 82Sin Pi38212 8073 ft We will use wrought return bends for this heater which is common practice. FRNC-5PC combines a process flow simulator with a com-.

Design Fabrication and Erection of Structural Steel For Buildings 2. Well cover various topics using the terms from the specification including. A refinery heater is one of the most important pieces of equipment in a refinery processing plant.

This guideline provides knowledge on how to design a furnace. 14724 East Proctor Avenue City of Industry CA 91746 Important Read these instructions carefully and completely before starting installation of the burner system. Every fired heater must have some type of safety system in place.

Constructional Features of Fired Heaters Fired Heater Casing. Recreate the search with a glitter polish and a toothpick or tiny brush dabbing meticulously to create your outlines. This guide is based on API 560 the industry standard for designing fired heaters in many industries including refining and petrochemicals.

Fired Heaters related important references. Fired heater design handbook Eunkyung likens this style to jewellery. The design and selection of a safety system starts with the evaluation of risk factors and risk tolerance.

This design guideline can assist to understand the basic design of furnace with suitable size material and heat of combustion. Refinery heaters firing provides a large part of the heat for the process. Design Parameters of a Large API 560 Heater.

This is an UNVENTED gas-fired heater. Coil Design Stack Burners Refractory System Operations Safety Alerts Firebox Explosion Excess Air Control Draft Control Fuel. FUEL GAS The air supply for many fired heaters is natural draft not forced air and these heaters typically lack the degree of automation applied to other process units in the plant.

Casing design temp Outside 82 C Radiant floor 91 C. Up to 24 cash back MANUAL ROBERT H. Best chemical engineering handbook chemical process calculations.

Natural draft fired heaters as the name implies use flue gas buoyancy to support combustion. Layout Considerations for Fired Heaters. This will result in the shortest possible flame length and more uniform heat distribution.

Struthers Wells a TEi line of products has been designing and supplying fired heaters and thermal fluid systems for more than 70 years. ANSIASME Standard B1201 Pipe Threads General Purpose Inch 4. API Standards 530 Recommended Practice for Calculation of Heater Tube Thickness in Petroleum Refineries 630 Tube and Heater Dimensions for Fired Heaters for Refinery Services 665 Fired Heater Data Sheet 3.

The characteristics of hot oil are listed in. Fired heaters -Source of high temperature heat Vertical Cylindrical Box Cabin Multi-cell Fired Reactors. Mechanical components of the heater Process design terms Heater draft configurations Lets get started.

To input into the thermal rating program Xfh we need to calculate the actual tube circle diameter which can be done using the following formula. Codes and Related Practices. Fired Heater Simulation Software FRNC-5PC is the worlds foremost computer program for fired heater analysis and design.

Know the Secret of Fired Heater Design and Operation with Ultra Low NOx Burner 3 1 Burner Design Parameters. Temperature CS can withstand is 440 degrees C however oxidation starts at 270 degc. Fired Heater Design Handbook.

21 Selection of number of burners Increasing the number of burners will reduce the heat liberation per burner. It is used in over 15 countries on 6 continents by leading petroleum refining engineering and construction and petrochemical firms. Their design and manufacturing expertise competitively supplies all types of fired heaters from small vertical cylindrical furnaces to complex specialty chemical petrochemical and refinery heaters.

I dont have to have a ring when I have these nails she says. The fired heater is separated into three sections which are the radiant section convective section and economizer section. This design guideline can assist in understanding the basic design of refinery heaters with suitable size materials of construction and heat of combustion.

Process Datasheet PDS Preparation.

Fired Heaters Working Components Types Function Sections Maintenance Pdf What Is Piping

Standards For Fired Heater Design An Assessment Based On Computational Modelling Sciencedirect

0 comments

Post a Comment